Reimagining Education for the New Collar Workforce

By Glenn Marshall and Doug Berger

Troubling Facts

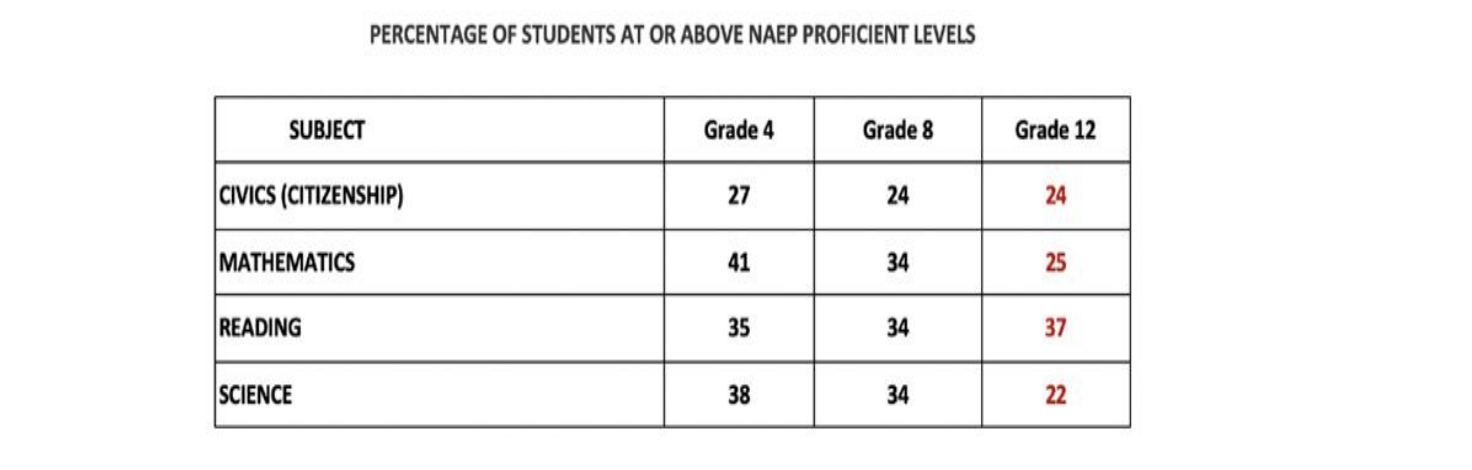

1) Even before the COVID-19 pandemic, students were facing the ongoing loss of learning opportunities that would shape the rest of their lives and the U.S. economic future. 2) The greatest challenge facing manufacturers of all sizes continues to be finding qualified workers (8th consecutive survey Manufacturers’ Outlook Survey from the National Association of Manufacturers). 3) Up to 85% of “new collar” jobs do not yet exist (Institute for the Future) so having transferable skills will be more important than a degree. 4) The latest National Assessment of Educational Progress (NAEP) 2019 report shows that only about 30% of students are proficient in civics, math, reading, and science at graduation as shown below.

5) In school year 2017–18, the national graduation rate for public high school students was 85%, the highest in the decade. However, only 37% met college readiness benchmarks.

6) Globally, the United States ranked 8th in reading, 11th in science, and 30th in math.

Underlying the facts is systemic failure … just not what you think

Education is trapped in an academic paradigm that has been increasingly irrelevant to blue collar, trades and now “new collar” workforce. The academic paradigm emphasizes intellectual knowledge; the new paradigm emphasizes know-how and skill. What is taught and tested in high school Math is algebra, geometry, trigonometry, calculus. The math skills the new collar worker really needs are arithmetic, measurement, graphing and statistics. What is taught and tested in high school English is expository writing and literature comprehension. The English skills the new collar worker needs are understanding instructions and step-wise action, filling out forms, writing plans, understanding a YouTube video to fix something and the ability to clearly explain. What is taught and tested in high school Science are principles, information and description in biology, chemistry and physics. Skills needed are understanding why and how things work, what Page 2 leads to failures and errors, what is unsafe and why. Skills to separate facts from opinions and conclusions, do analysis and run experiments. What we do not teach includes computer programming, digital applications, problem solving methods, visual sketching an idea. We do not teach that often there is no single right answer. The academic paradigm does not develop character. Inside the academic paradigm we do not value the teamwork, resilience, commitment; we develop those from sports and performing arts. We do not value the responsibility, discipline and adaptability from serving in the armed forces. These are critical to the needs of employers. We live in a world where ‘there is an app for that and people’ and people figure them out with no instructions, hack them, play video games at increasing difficulty and we say they are not lifelong learners.The new paradigm is skilling

Manufacturers, educators and economic development professionals everywhere are looking for real, actionable ideas to train workers, reduce the shortfall and realize the potential of the new age of manufacturing. The new collar workers that manufacturers seek have the digital skills needed to “run automation and software, design in CAD, program sensor, maintain robots, repair 3D printers and collect and analyze data” according to Sara Boisvert, author of The New Collar Workforce. The President and CEO of The Reshoring Initiative® Harry Moser is dedicated to educating manufacturers on the importance of manufacturing to the U.S. “The government needs to take some real action to push funds into training programs instead of university loans,” said Moser. “The biggest issue in the reshoring movement is the skills gap,” says Don Buckner, President and CEO of MadeinAmerica.com. Career Technical Education (CTE) as an educational strategy to equip learners with the academic and technical skills they need to be prepared for future careers. Today’s CTE delivers real options for college and rewarding careers, helps learners build real-world skills and enhances the high school and college experience. CTE is having a positive effect on career-ready graduation rates: 95% of CTE students graduate high school, 10% higher than the national average. Seventy eight percent of CTE graduates enroll in post-secondary education full-time. To better prepare recent graduates for all types of new collar jobs, the Report Card on Workforce Readiness recommends that all stakeholders (businesses, educators, and community members) consider methods of enhancing important workplace skills. It suggests internships, summer jobs, work-study programs, job shadowing, and other educational approaches that include real-world experiences or community involvement, provide opportunities for students to acquire basic knowledge and skills, while cultivating applied skills. According to the report, the top three applied skills that employer’s value the most are professionalism/work ethic, teamwork/collaboration, and oral/written communications. The future skills are nowhere to be found in public education. Based on extensive research in 2019 with a select committee, MSSC has chosen nine emerging 4.0 technologies it believes will profoundly influence manufacturing and quality control processes: 5G, artificial intelligence (AI), autonomous robots, additive (3D), data analytics, Industrial Internet of Things (IIoT), augmented reality, nanomanufacturing, advanced materials.

The future of skilling the workforce is happening … it is just not widely scaled.

The Manufacturing Skill Standards Council (MSSC) is a nationwide system based upon industry defined and federally endorsed standards. It offers both entry-level and incumbent workers the opportunity to demonstrate that they have acquired the skills increasingly needed in the technology-intensive jobs of the 21st century. Nonprofit organizations like Project Lead the Way and SkillsUSA are partnering with school districts and businesses and providing students with real world pre-engineering and pre-business experiences. High school students who complete these programs have a more solid foundation for understanding manufacturing and landing that first job. In Virginia, New Horizons Regional Education Centers (NHREC) is the largest of the nine regional centers and annually serves 1,500 public school students and 1,200 adult learners. New Horizons is state-of-the-art, and a national authority on workforce educational programs and services. NHREC in partnership with Newport News Shipbuilding (NNS) Apprentice School has launched Youth Builders (YB), a pre-apprenticeship program. Youth Builders courses are “high tech” hybrid courses that strengthen students’ readiness for the apprentice program. They provide face-to-face mentoring. YBs are exposed to enriching workplace learning activities. Apprenticeships are the new gold standard. “The U.S. will bring back millions of manufacturing jobs when its apprenticeship system goes from being a laggard to a world leader,” Harry Moser, the Reshoring Initiative. ToolingU-SME is the world leader in providing on-line, instructor lead and hybrid skill based courses. It is working with over 600 community colleges to provide students with training and pioneering the use of advanced technology in workforce skilling including augmented reality and virtual reality. The Association for Manufacturing Excellence (AME) has a network of North American consortia, which are clusters of local companies that collaborate to accelerate lean and continuous improvement through sharing best practices and lessons learned. Attracting, onboarding and training the new collar workforce is a core area of focus. These are proven programs that a community can adopt to serve their students, parents, teachers, and taxpayers and graduate career ready citizens, skilled to compete in the global manufacturing economy.The Pathway Forward

America needs an educational renaissance alongside the Industry 4.0 technology revolution. The authors refer to this as Industry Reimagined 2030 bringing about a sea-change in our collective thinking and actions. Led by public-private partnerships of national associations, educational institutes, and manufacturers to collaborate and speak with a unified, compelling voice to reimagine the future of U.S. industry for the next generation. Glenn Marshall, the Association for Manufacturing Excellence (AME) Management Team initiative for a “Manufacturing Renaissance,” member of the Reshoring Initiative, Job Creators Network, Industry Reimagined 2030. Contact marsh8279@aol.com. Doug Berger, founder Industry Reimagined 2030, bringing about a sea-change in US industry from a worldview of ‘inevitable decline’ to one of ‘vibrant opportunity.’ Contact doug.berger@ir2030.org ---

Glenn Marshall, the Association for Manufacturing Excellence (AME) Management Team initiative for a “Manufacturing Renaissance,” member of the Reshoring Initiative, Job Creators Network, Industry Reimagined 2030. Contact marsh8279@aol.com. Doug Berger, founder Industry Reimagined 2030, bringing about a sea-change in US industry from a worldview of ‘inevitable decline’ to one of ‘vibrant opportunity.’ Contact doug.berger@ir2030.org ---