LeanShoring with Augmented Reality: Turning "Made in America" into Reality

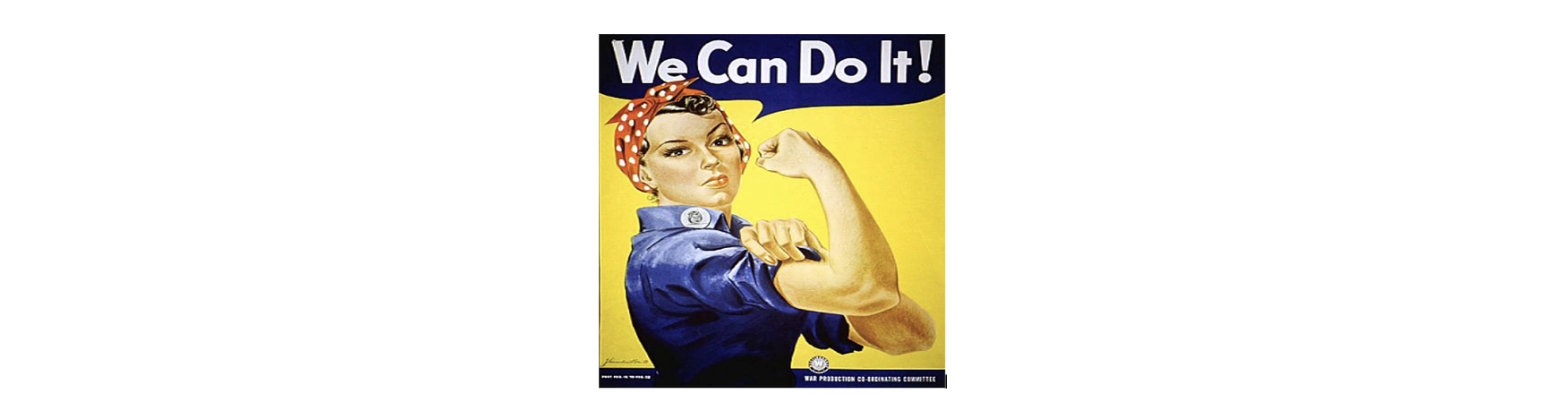

After World War II, the U.S. produced half of the world's industrial output and almost 100% of what the U.S. consumed, but these shares dropped significantly due to offshoring. Recently, reshoring has accelerated as companies invest in domestic supply chains and a skilled workforce of new-collar professionals.

President Donald Trump described this as a “golden age for American manufacturing,” highlighting job growth driven by new technologies. New-collar jobs combine aspects of white- and blue-collar work, prioritizing specialized skills over college degrees. Workers can enter these well-paying careers through community colleges, certifications, apprenticeships, or internships. Manufacturing and shipbuilding face an aging workforce and a lack of vocational training and apprenticeship programs. Expanding apprenticeships would boost U.S. manufacturing jobs more than tariffs or other industrial policies (Reshoring Initiative’s 2025 Survey). OEMs increasingly are hiring based on skills and experience, rather than just degrees. Emerging artificial intelligence (AI) and augmented reality (AR) roles offer more opportunities for those with technology certifications or relevant skills, often needing only a high school diploma plus math and science proficiency. The Association for Manufacturing Excellence (AME) supports reshoring, nearshoring, and LeanShoring™. LeanShoring uses Lean Six Sigma principles and advanced technology to reduce costs and improve efficiency and delivery, to build resilient supply chains and promote ongoing continuous improvements. This approach is intended to decrease manufacturing and shipbuilding costs, reduce inefficiencies, and enhance competitiveness, productivity, and sustainability. The Reshoring Initiative® offers the free TCO Estimator® to help businesses compare costs of offshore vs. domestic production and sourcing. Endorsed by the U.S. Commerce Department, this tool supports sourcing decisions for all types of organizations. Domestic production brings benefits like shorter lead times, higher quality, branding advantages, tax incentives, reduced inventory, greater flexibility, lower IP and geopolitical risks and no tariffs. Smart Facilities are expected to drive reshoring along with job growth across industries. By integrating automation, data analytics, AI, and augmented reality, these facilities enhance productivity, streamline quality checks, and improve process oversight. New technologies and mobile platforms will give workers tools to boost efficiency and uphold quality standards. Augmented reality technologies offer features such as step-by-step visual instructions for operating equipment. By displaying information—including procedural steps, safety warnings, expert input, schematics, and digitized data—AR supports knowledge transfer where it is needed. Newport News Shipbuilding (NNS) is implementing Augmented Reality to drive innovation, safety, quality, and efficiency in shipbuilding. AR overlays digital information on physical environments using devices like tablets, aiding tasks such as comparing 3D models to real structures, planning, maintenance, and safety checks. Prioritizing AR use where it adds most value—like reducing errors or improving safety—supports skilled workers and helps maintain U.S. manufacturing competitiveness as mobile technology becomes more integral. Shipbuilding has undergone changes since World War II. Huntington Ingalls Industries’ Newport News Shipbuilding, located in Newport News, Virginia, has built all nuclear-powered U.S. Navy carriers, including the Ford-class USS Enterprise (CVN 80), which is the first carrier constructed entirely using digital platforms. Shipbuilders now use handheld tablets with 3D renderings, indicating a shift towards digital and paperless processes. Experts suggest that increasing the use of smart manufacturing and shipbuilding technologies will help American industry become competitive globally, especially as the fourth industrial revolution unfolds. Join us at the 41st AME International Conference in St. Louis, Missouri, October 6–9, 2025, to learn how AI is your Gateway to the Future and Beyond while networking with continuous improvement professionals from around the globe. - - - Glenn Marshall is a member of the Association for Manufacturing Excellence (AME) Southeast board of directors for 13 states, the Reshoring Initiative, and a career pathways volunteer for Newport News Shipbuilding (NNS) (retired). Email him at marsh8279@aol.com.